THE FURROW.

Read the details

“WITH SLURRY, YOU CAN FERTILISE WITH PRECISION”

The strict legislation on fertilising with slurry is causing quite a stink for many farmers. Farmer Stefan Vogelsang explains why it’s still useful and how it can be done without stress.

Stefan Vogelsang heads one of the Water Framework Directive‘s 31 model enterprises in North Rhine-Westphalia which test innovative techniques to advance farming, protect groundwater and use fertiliser more sparingly and efficiently.

MR VOGELSANG, WHAT ROLE DOES SLURRY PLAY IN YOUR ENTERPRISE’S FERTILISER PLANNING?

Slurry is important because it is a compound biological fertiliser. I use it for its vast range of nutrients as well as to achieve a circular economy on the farm: The animals turn what I feed them into excrement and this then goes onto the field, thereby going back into the cycle.

THERE’S A LOT OF TALK ABOUT SLURRY. WHEN IT COMES TO SLURRY AND PLANNING FERTILISER REQUIREMENTS, WHAT DO YOU NEED TO KEEP IN MIND?

Slurry has a bad reputation, and wrongfully so. With slurry, you can fertilise with precision and determine nutrients. As farmers, we typically do this by first stirring up the slurry and taking a sample, which a lab then analyses to find out its exact makeup. This is the foundation for planning fertiliser requirements. There are many factors to consider: Average yields, soil types, which crops we grow, crop rotation, catch crops and more. We calculate all of this which then allows us to determine the fertiliser requirement. And this fertiliser requirement is the legal upper limit which we’re not allowed to exceed.

Stefan Vogelsang manages one of 31 Water Framework Directive model farms in North Rhine-Westphalia.

HOW DOES THIS SLURRY ANALYSIS USUALLY WORK?

It’s really important to obtain a representative sample of the slurry. The lab only analyses half a litre of slurry which needs to represent the four million litres of slurry that are in my storage tanks. That means I need to stir up the slurry very well to make sure the liquid is evenly mixed so we get a representative sample. The sample gets sent to the lab and I get the results 10 days later.

THAT SOUNDS LIKE A LOT OF WORK. IS THERE ANOTHER WAY?

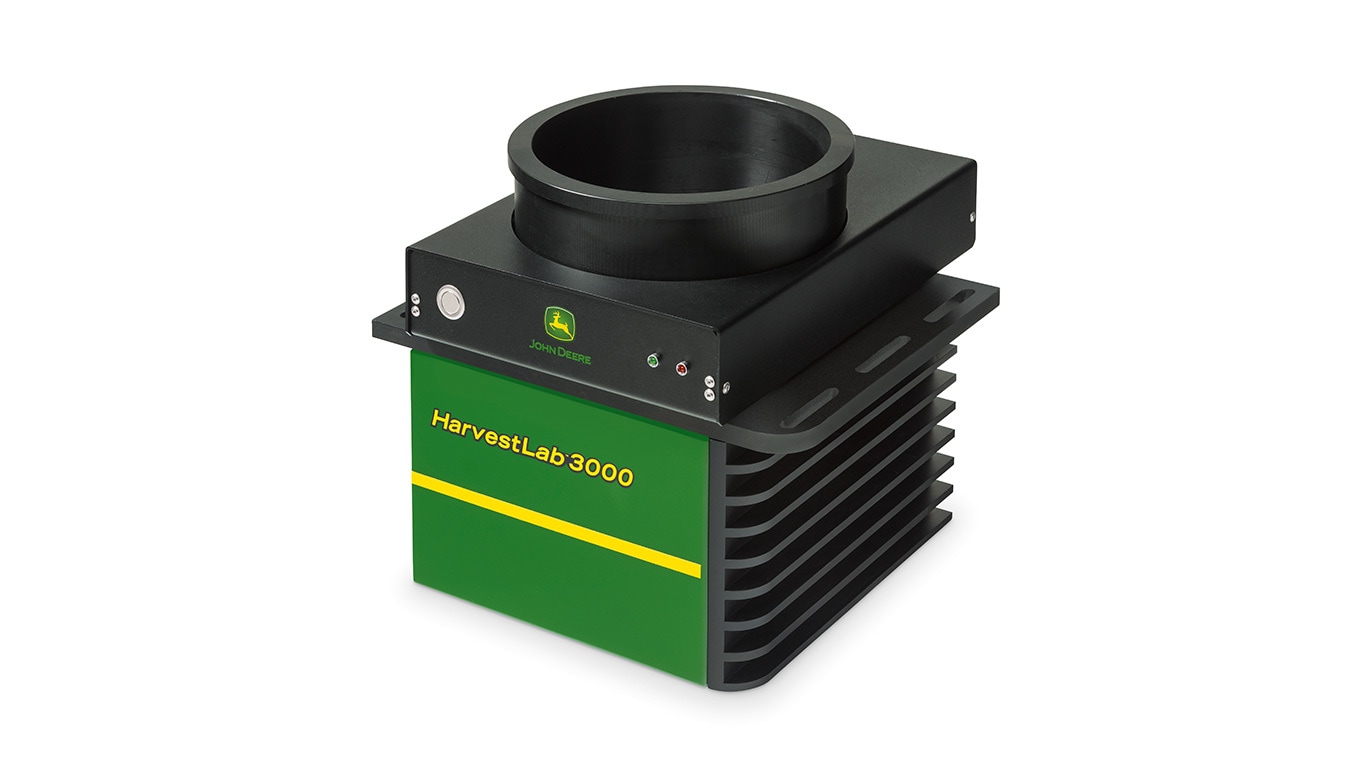

HARVESTLAB 3000

Near-infrared (NIR) spectroscopy to analyse various constituents within harvested crops, silage or slurry (one sensor, three applications)

Yes, there is a better way. We’ve been using the Harvest Lab™ 3000 NIR sensor in our business for the past five years; this allows us to analyse our slurry in real time. This saves us from having to stir it up in advance: If I want to spread slurry, I don’t have to stir it up 10 days in advance, take a sample wait for the results. I can stir up my slurry just before taking it to the field, evaluate it there and spread it according to the nutrients it contains, thus ensuring consistent crops across the board.

HOW DOES THE SENSOR WORK?

A pump takes in the slurry and pushes it along through a pressure line, where it passes the sensor and into the spreading device at the rear. The sensor evaluates the makeup of slurry in real time during spreading. The sensor is connected to an ISOBUS wiring harness. This lets me see the data transmitted by the sensor on the terminal right in front of me in the tractor cab. I can enter a target value there which is what the slurry drum needs to work towards. The HarvestLab™ 3000 controls this value automatically.

The sensor of the HarvestLab™ 3000 measures the nutrient concentration live during application.

SO YOU HAVE YOUR OWN ON-BOARD LAB WITH YOU AT ALL TIMES AND KNOW EXACTLY WHICH NUTRIENTS AND HOW MUCH OF THEM THE SLURRY CONTAINS. DOES THIS BENEFIT ONLY YOUR BUSINESS?

We also supply slurry to arable farming enterprises. This is beneficial for them because we can document everything in detail when we spread slurry for them. We have an overview of the nutrients in the Operations Centre and after the work is done, we can create a printout showing which nutrients were applied and how much on certain days. We can report this directly in the online database, meaning we are in compliance with the law straight away. This also lets farmers check if they have actually received the nutrients that they ordered.